Serbia emerges as a key point of cooperation with Denmark, linking industry, education and sustainable development

CORPORATE INTERVIEW

by Dragan Nikolić

Grundfos, one of Denmark’s leading industrial companies, has been present in Serbia for 15 years, positioning its Inđija factory as a regional hub for production and innovation. We spoke with Veljko Todorović, Country Director of Grundfos Serbia, about the company’s role in green transition, partnerships with universities, and how sustainability shapes both business and society.

How would you describe the essence of the Danish approach to business, and in what way are these values – particularly sustainability, inclusiveness and innovation – transferred and developed through Grundfos Serbia?

I believe it is exactly as you said. Sustainable business is one of our core values. When we talk about sustainability, we do not mean only financial sustainability. Still, above all, the contribution we make through our work to humanity as a whole, to the country, and the planet.

As for innovation – how is it reflected in our operations? Quite simply, we are strongly connected to all the processes taking place within Grundfos – from production, through company-wide operations, to product development. This focus is embedded in everything we do and build in Serbia. Our factory has been awarded the LEED Gold certificate and is a truly sustainable building. The systems we have installed are state-of-the-art solutions in terms of sustainability, aimed at reducing the overall impact on the environment.

Our factory in Serbia has become a showcase of what sustainability means

Grundfos was among the first in the sector to implement SBTi targets for reducing CO₂ emissions. How challenging was it to align such ambitious climate goals with the requirements of everyday production?

SBTi targets encompass three scopes. Scopes 1 and 2 refer primarily to our internal emissions and the footprint we leave through production and logistics processes. However, the largest share of emissions comes from the products themselves – specifically from their use throughout their entire life cycle. Although our share in global emissions is only about 1–1.5 per cent, it is the use of products that creates the greatest impact.

Grundfos is known as the first company to introduce frequency-controlled motors, which significantly reduce electricity consumption. This is an innovation we continue to develop and elevate to an even higher level. Naturally, this brings certain challenges. Such products are more expensive, so it is necessary to find business models and ways to place them on the market at a competitive price. It is not simple, but this is exactly why we exist as a company – to seek out and deliver such solutions.

Inđija has become one of Grundfos’ key hubs worldwide. What are the reasons for such a strategic position of Serbia in your global value chain? And, to begin with, could you explain what exactly Grundfos has in Inđija as part of its global operations?

In Inđija, we currently have one factory with two buildings covering a total area of 41,000 square metres. This includes two production halls, an administrative building and a warehouse. In addition, we use a rented building in the IT park across the street from the factory, which houses.

Serbia offers a qualified and educated workforce. We indeed lost a certain continuity due to the events of the 1990s and early 2000s, and we fell somewhat behind in industrialisation processes. Nevertheless, our education system still produces people who are capable of learning quickly and applying the necessary technical knowledge.

On the other hand, I believe there is also a mindset here – a strong motivation to show that serious projects can be carried out in Serbia. And we have succeeded in that. We started the factory with a small team, and two years ago, we went through Grundfos’ global factory certification process. At that time, we were assessed as the best Grundfos factory – not in terms of size, but based on all the indicators and processes used to evaluate operations. We have also trained people who now support other divisions and segments of the organisation, and the value they create from Inđija is recognised globally within Grundfos.

The company is majority-owned by a foundation. How does this ownership model shape long-term decision-making, and how different is it from traditional corporate governance?

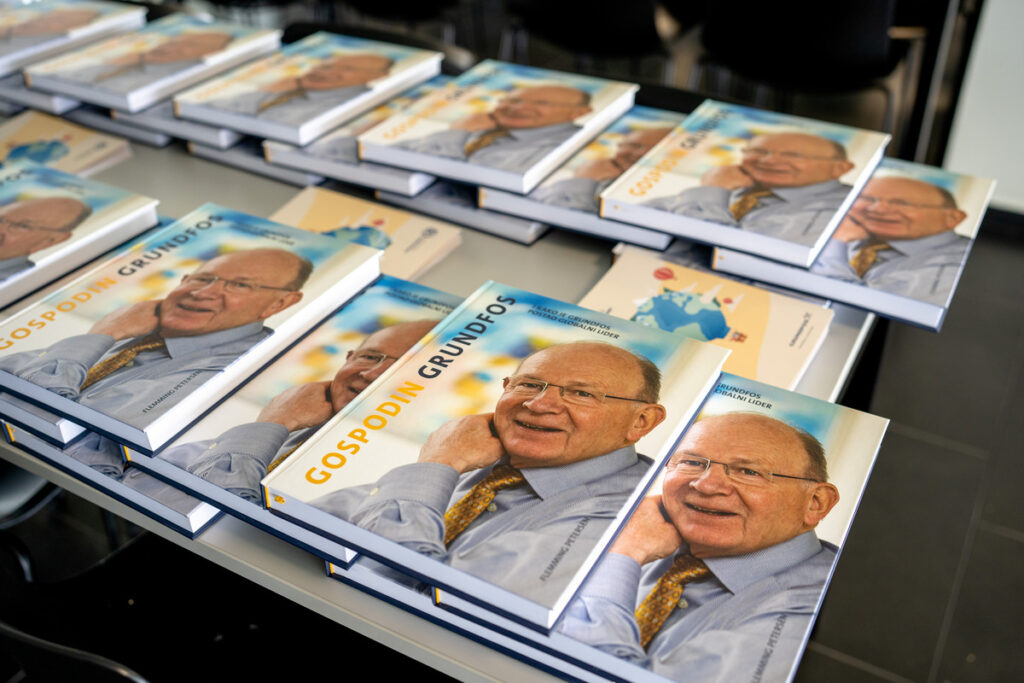

Our company is privately owned, which means we are not listed on the stock exchange. The main owner of Grundfos is the foundation established by our founder, Poul Due Jensen, precisely to protect the financial integrity of the company.

This ensures that the company always serves its original purpose – dealing with water and systems that use it efficiently and reduce environmental impact.

Profit is therefore used primarily to finance new development projects and expand our global impact, rather than to satisfy shareholders. Employees are also small shareholders, and the profit we generate is channelled mainly into innovation and product development, further increasing our positive impact worldwide.

How viable is a non-traditional, non-corporate business model in today’s era of neoliberal capitalism, where profit is paramount and everything else is secondary?

Honestly, I believe this model gives us an advantage rather than being a burden. Grundfos is a company with a strong purpose and a culture rooted in the legacy of our founder, his son and now his grandson as CEO.

People stay with Grundfos for decades because they can align their values with the company’s values. This model also allows for simpler decision-making, as we are not tied to the short-term demands of the stock market. Ultimately, it is a different system of values from the one that dominates today, but precisely those values, culture and purpose are what guide us.

You have invested in a wastewater treatment plant, the “BioBooster”, in Serbia. Are similar investments planned in other local communities, and how important are such projects for the company’s reputation?

We no longer call it “BioBooster”, as that was the name of a former organisation, but the essence is that we now have a system for water recirculation. It enables us to turn grey or black water – including rainwater – into drinking-quality water, which is then reused in the system, reducing both the water we take from the network and the amount discharged into sewage.

As far as we know, this is the only such example in Serbia. Our plant operates autonomously, processing only our water, and we now have a 250-cubic-metre tank for rainwater, with capacity still expanding. The treated water is used for toilets, cooling towers and other needs, further reducing consumption. For us, this project was a showcase of what can be achieved and how we approach sustainability. It may never fully pay off financially, but it is a concrete project, not just a story, and it remains highly important for our mission and purpose.

Has this facility proved to be financially viable?

No, it has not been financially profitable. But in terms of impact – yes.

Did it perhaps inspire you to continue further, or encourage others in Serbia to do something similar?

Unfortunately, not, as water here is still seen as abundant and often taken for granted.

What matters, however, is that our Serbian factory has been designated a so-called VIP factory – one of only three in the world where we bring our most important customers. We use this facility as a demonstration to show what can be achieved and to inspire partners not only in Serbia but globally. So even if it has not brought financial profit, it has become a valuable example and a model that proves things can be done differently.

A company without its people does not exist

How do you see the development of relations between Denmark and Serbia in the context of innovation, education and the green transition? Can Grundfos serve as a bridge for further cooperation projects?

We are, in many ways, the largest representative of Danish industry in Serbia. Grundfos sees Serbia as a key hub, especially for our domestic pumps division, but our operations here also include development, marketing, HR and finance – making the Inđija factory highly significant.

Over the past 15 years we have built close cooperation with the Danish Embassy and universities. This year we launched a summer school enabling students from Serbian faculties to spend time in Denmark working on innovative projects, and I hope such initiatives will continue to grow.

Denmark is a world leader in renewable energy, and there is Serbia can learn. With the right will and connections, cooperation in this field will only become stronger.

You have held the Top Employer title for three consecutive years. What, in your view, sets you apart in human resources and how do you build a corporate culture in an industry often perceived as “technical”?

A company cannot exist without its people, and our approach is rooted in openness, trust and genuine care for employees. We encourage transparent communication, listen to feedback and make sure suggestions are implemented.

Leadership here is based on respect and equality rather than hierarchy, and we pay close attention to wellbeing, development and integration of young talents.

That combination of values is what makes Grundfos a Top Employer – not just an award, but a culture our employees truly experience.

Photos: Grundfos Serbia