A 45MW big battery now under construction for mining giant Rio Tinto’s massive iron ore operations in Western Australia will be the biggest of its type in the world and will give valuable insight into how the country’s main grid can also manage the switch to wind, solar and storage.

The battery at Tom Price in the Pilbara will have little more than 15 minutes of storage, or just 12MWh, but it is the ability to operate as a “virtual synchronous machine” (VSM), also known as a “grid forming inverter”, that is the key to this project.

The importance of this technology is that it allows the operators of the private network to switch off expensive and highly polluting gas turbines they currently use as a constant backup for their existing fossil fuel generators. These batteries allow the shutdown of backup turbines, allowing great fuel savings, reduced emissions and better reliability, as they can maintain the grid if a problem occurs until the backup generators are turned on. The battery will be able to control the grid and hold it steady by itself if needed. This, in turn, is a key step to designing battery inverters and software that can support a 100 per cent renewable grid.

But according to Stephen Sproull, a senior engineer at Hitachi ABB, the 45MW, 12MWh Tom Price battery will be the biggest of its type in Australia, and the biggest battery in the world that is not connected to a national interconnected grid. Its significance, however, is not so much in its size, but what it means for the future of much bigger grids such as Australia’s National Electricity Market. “The aim is to switch off synchronous machines such as gas turbines today, but also lay the technical foundation to operate with no synchronous generators in the future and source all electricity from renewables,” Sproull told RenewEconomy in an interview. “It’s important to demystify the technology, and make it clear that we have the technology to provide the essential grid services and get to 100 per cent renewables.”

In these sorts of grid gas – or diesel power – is supplied by multiple turbines. Two or three might be producing the electricity needed to meet demand, but fossil fuel turbines need back up, and another one or two must keep spinning, and burning, fuel, 24 hours a day, 365 days a year in case of an incident.

Sproull says grid forming inverters are unlike normal inverters because rather than just following the frequency and voltage waveforms of the grid, they can create their own frequency and voltage wage forms. They are often used on small, off-grid installations. But the virtual synchronous machine software that overlays these grid forming inverters teaches them how to behave with the rest of the grid, and to interact with other technologies and installations.“Instead of just running their own race, and fighting other installations, it acts as a bit of a shock absorber so it can provide a holistic and unified response,” Sproull says. This is crucial for a future grid without synchronous generators because it means that batteries can control the system and work together.

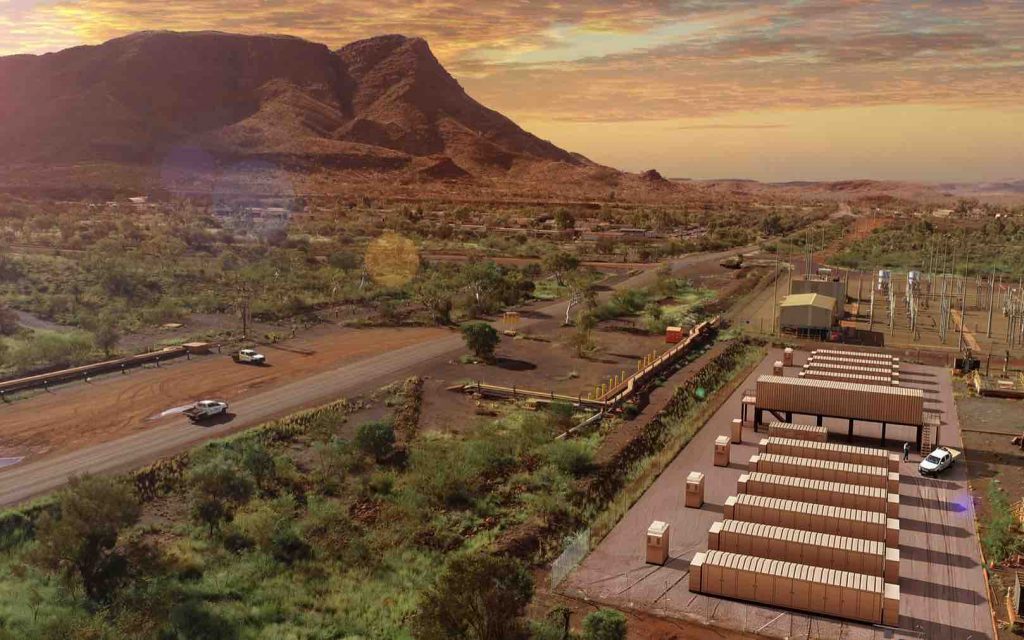

The Tom Price batteries are being assembled in Perth, using Hitachi ABB inverters and Kokam batteries, before the containers are shipped to the mine site at the end of the year, where it will be installed next to the existing sub-station and integrated into the network (see artist’s image above).

Source: Reneweconomy.com.au